Child Resistant Bags

The #1 Child Resistant Flexible Packaging Solution

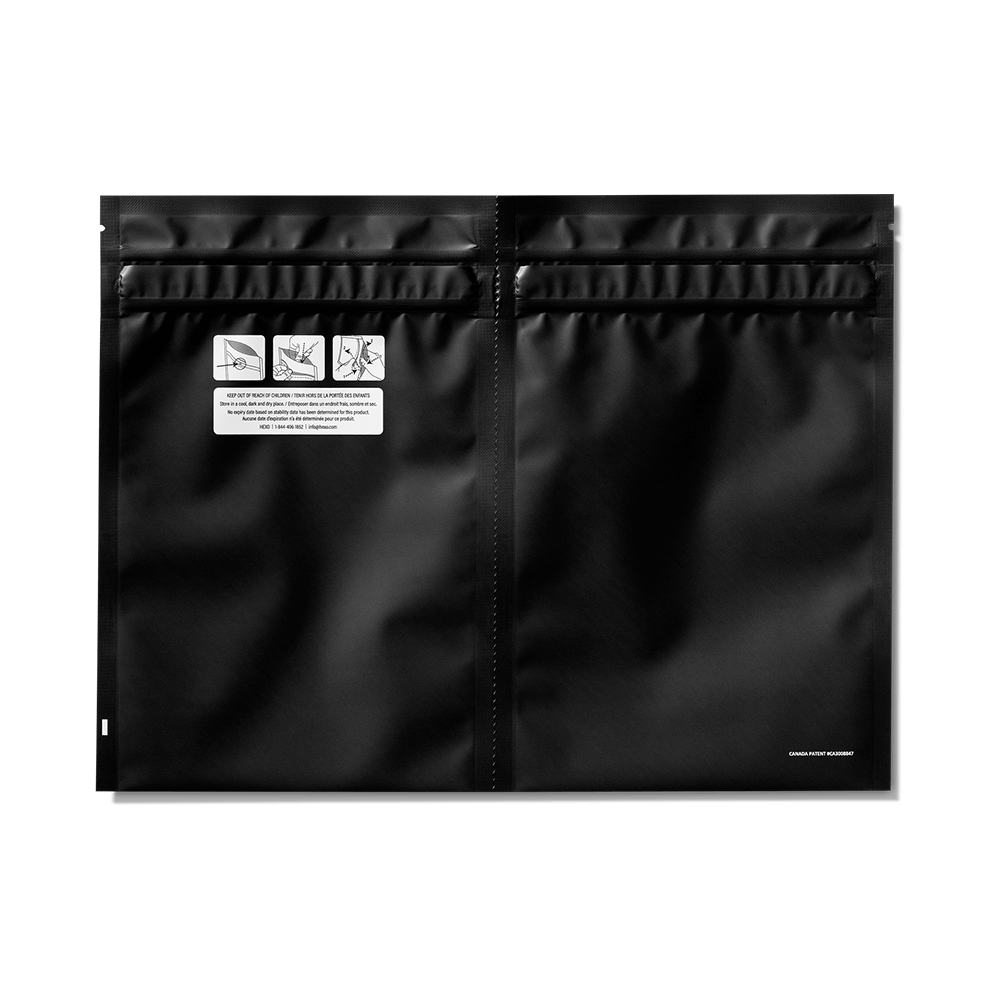

Introducing Secure Sack: the world’s first lab-certified child-resistant bag. With its patented locking press to close zipper, thick food-grade plastic, and extra durable flexible construction, these child-resistant packaging pouches provide peace of mind to parents, dispensary owners, and law enforcement officials by safeguarding many dangerous and toxic items that don’t fit into a pill vial. We offer the Secure Sack child-resistant bag in a variety of colors, sizes, with add-ons like vape cartridge inserts and more.

Dymapak Secure Sacks are classified in accordance with ASTM D3475 and are lab tested and certified using CPSC standards and protocol to conform to the requirements of a Poison Prevention Package (CPSC 16 CFR 1700 child resistant).

Patents: US, Canada, Germany; Patent-Pending: UK

Child-Resistant Pouches are Perfect for:

Medicine & Vitamins

Batteries & Small Objects

Cleaners & Detergents

Cosmetics & Personal Care

Why You’ll Love Our Child-Resistant Bags

Our industry-leading Child-Resistant Bags feature a patented press & seal zipper design that creates a moisture and smell proof barrier that can safely store and secure medicinal flower products, concentrates, edibles, vape cartridges, and other infused products.

Tamper-Evident Seal

Ensures integrity of the contents

Easy Grab Tab

Our patented mechanism makes it simple to use

100% Opaque

Contents are kept discreet and protected from light degradation

The World’s First Recyclable PCR Child-Resistant Pouch

Introducing Secure Sack Eco: the world’s first recyclable lab certified child-resistant pouch, now available with 33% postconsumer recycled content (PCR). Using our highly acclaimed and patented Secure Sack child-resistant press to close mechanism, these child-resistant bags reduce the impact of plastic packaging on the environment without sacrificing the moisture and oxygen barrier properties of metallized film, nor the safety assurances needed when storing hazardous and poisonous items.

Store Drop-off Recyclable

Reduces the impact of plastic packaging on the environment

Tamper-Evident Tab

Additional protection for your contents

100% Opaque

Contents are kept discreet and protected from light degradation

Child Resistant Bags reduce your:

Carbon Emissions

Shipping Costs

Environmental Impact

Waste Profile

Customization Details

10 days*

Lead Time

5000 pcs

Minimum Order

Worldwide

Shipping

Customize your pouch

Every product has unique packaging needs and there’s nothing comparable to flexible packaging for meeting a wide range of needs. We have extensive experience, knowledge, and resources to tailor pouches to your exact requirements, ensuring the product integrity and the safety of your customers.

We offer every material and finish

- Glossy

- Holographic

- Hot Stamped

- Kraft

- Matte

- Metallized

- Padded Thermal Control

- Post Consumer Resin (PCR)

- Recyclable

- Soft Touch Matte

- Spot Matte/Spot UV

Specialized Solutions

Certifications

Your trusted child-resistant packaging partner

Dymapak’s child-resistant pouches are the perfect compliant storage option for pharmaceutical and CPG applications as well as producers of cannabis products across the globe. Not only are the child-resistant mylar bags the most stylish on the market, but they are also compliant as a “Container”, “Immediate Package” and as an “Exit Package” under all state laws. Our smaller size child proof bags can be used as primary packaging, and the larger size child proof bags can be used as secondary child-resistant packaging.

Stock Styles

Work With Us

Contact Us

Need more information about our Child-Resistant and non-CR products? Contact us by filling out the form or by calling us at 917-210-1067

Frequently Asked Questions

Do Dymapak’s child resistant bags meet the Consumer Product Safety Commission’s (CPSC) Certified Child Resistant Packaging requirements?

How are Dymapak’s child-resistant bags different?

What are Dympak’s child-resistant bags made out of?

What are Dymapak’s child-resistant bag customization options?

About child-proof packaging

Child-Proof Packaging: Why Does It Matter?

How To Protect Children With Safe Packaging

Why Child-Resistant Packaging Is Essential for Cannabis

Sustainable Child-Resistant Packaging: Better for Kids and Planet

Types of Child-Resistant Packaging

Why Is Mylar the Most Popular Choice for Child-Resistant Packaging?

What Is Polyethylene?

Mylar Bags Are Safe for Cannabis

Summary