Polyethylene Recycling: How Does It Work?

We all use plastics in our daily lives, so when it comes to making purchasing and manufacturing decisions, recyclability is a foremost concern for many of today’s brands.

Eco-conscious consumers now expect packaging materials that align with their environmental goals without compromising product quality and freshness.

For today’s brands, polyethylene (PE) can be a practical choice for its recyclability, durability, and versatility in a range of applications. Although not everyone may be familiar with PE by name, it is ubiquitous and found in many common household goods.

Why should your brand care about PE, and how can it be helpful in reaching eco-conscious goals? Let’s dive deep and see how PE recycling can work in your favor.

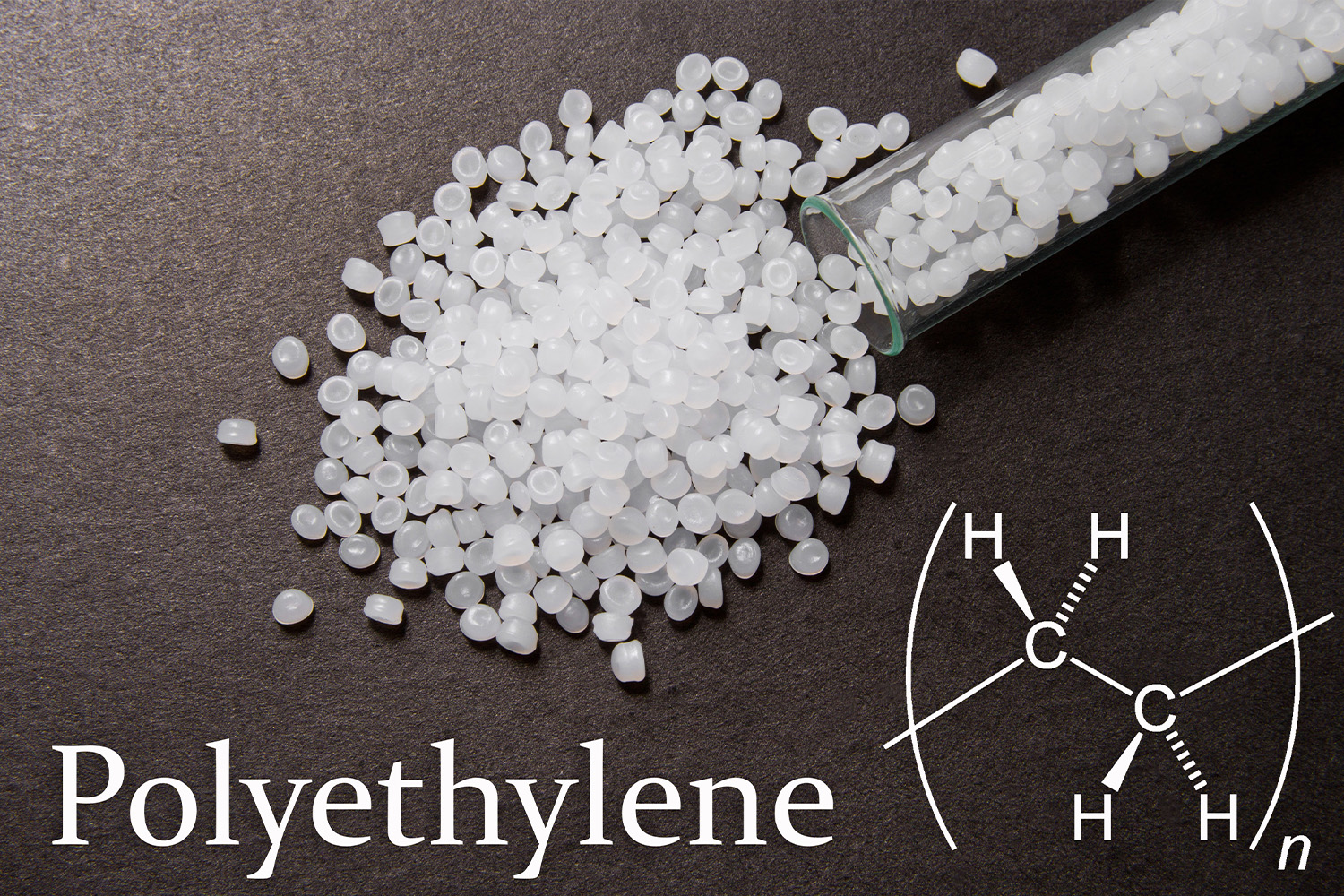

What Is Polyethylene (PE)?

Polyethylene is a thermoplastic product, meaning it is made of polymers that become liquid at high temperatures and solidify once cooled. This makes PE highly durable and useful in many applications.

PE is the world’s most commonly used consumer packaging plastic, and it comes in many different forms, each with unique characteristics and uses.

For the purpose of this article, we will discuss two of the major types of PE: high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

High-Density Polyethylene (HDPE)

HDPE is a versatile plastic made from petroleum. Due to its high melting point in the range of 120 to 130°C, HDPE is highly malleable and, once cooled, remains rigid under most conditions.

With a high strength-to-density ratio, HDPE is a lightweight, tough, and durable plastic. Unlike its flexible and transparent counterpart LDPE, HDPE is denser and more opaque.

HDPE is used to manufacture the following products:

- Bleach bottles

- Milk jugs

- Cutting boards

- Piping

- Wood-plastic composites

- 3D printing filament

- Water bottles

- Shampoo bottles

Low-Density Polyethylene (LDPE)

LDPE is a thermoplastic made from the monomer ethylene. LDPE is softer, more transparent, and more flexible than its sister plastic HDPE. However, its lower melting point of about 110°C makes it unsuitable for high-heat environments, as it will become soft and weak.

LDPE is most often used in film applications because of its toughness, transparency, and flexibility. Its resistance to acids, bases, and vegetable oils makes it an ideal plastic for food applications.

LDPE is commonly used for the following products:

- Food containers

- Shrink wrap

- Pallet wrapping

- Grocery bags

- Plastic film

- Squeezable or single-use plastic bottles

- Plastic containers and tubs

Both HDPE and LDPE are low-cost and easy to process, especially when compared with manufacturing steel and other materials. Both are food-grade, or food-safe, plastics.

Both plastic types are used to make plastic piping. You can usually find these in the same areas as you’d find pipes made from polyvinyl chloride (PVC).

Can Polyethylene Be Recycled?

One of the great appeals of PE is its recyclability and reusability. This is because PE can be heated and cooled repeatedly without significant deterioration. At its melting point, PE is liquid, which means it can be molded to create new products.

PE is one of the most popular recyclable types of plastic, alongside polypropylene, polyethylene terephthalate, and polycarbonate.

How Does Polyethylene Recycling Work?

PE products begin their second life in recycling facilities. At these plants, post-consumer products are sorted by thickness and according to their recycling code. HDPE has recycling code #2, and LDPE has recycling code #4. This separation occurs because PE products, like plastic bags, packaging, or piping, must be processed using different equipment.

In order to go through another journey through the manufacturing process, the PE must be clean and free of any residual substances. Recycling centers take these sorted products and clean them thoroughly before proceeding with the next steps.

If a product is not 100 percent HDPE or LDPE, it must then undergo the process of homogenization, which is the separation of PE from the other components.

Recycling companies primarily use two different processes to achieve homogenization:

- Sink-float separation – A process in which materials of varying densities will float at different levels in a liquid so they can be subsequently separated.

- Infrared radiation – A process that uses infrared radiation to distinguish unique near-infrared signatures (NIR).

Once separated, cleaned, and homogenized, the PE can then go through the process of granulation. Granulation begins with shredding the PE. It is then heated to the melting point and formed into new PE pellets. These pellets are then combined with some virgin PE (PE that has not yet been recycled) to create new plastic products.

Common products in the plastics industry that are manufactured with recycled plastic materials include plastic lumber, curbside waste management or recycling bins, pipes, shopping bags, and beverage bottles.

Issues With Polyethylene Recycling

Although there are many great benefits to polyethylene recycling, there are a few challenges worth mentioning.

As outlined above, in the case where products are created of a composite of PE and other products, the separation process can be quite intensive. Incineration is often favored as an option, which prevents the PE from entering its second life of utility.

Consumers may not always be familiar with the resin identification codes (RICs), which are numbers on plastic products that are used to help recycling plants sort plastics more efficiently. Because of a lack of proper education, confused consumers may throw products into the trash that could be recycled instead.

What Are the Benefits of Polyethylene Recycling?

Polyethylene recycling has many benefits for both businesses and consumers.

Environmental concerns are at the top of the list for the typical modern consumer. Changing production techniques and demonstrating a commitment to recycling and sustainable practices can help build brand loyalty.

Here are just a few of the benefits of PE recycling.

1. Sustainability

The natural resources on Earth are finite, so it is important that we treat them with care, use them at sustainable levels, and get as much repeated use out of them as possible.

Recycling is a major cornerstone of a sustainable strategy. Because we use so much plastic in the course of our daily lives, sustainability should be the goal for any eco-conscious brand’s packaging strategy.

The good news is that, due to its malleability and ease of processing, most recycling plants around the world accept PE plastics. Unlike other materials that cannot be sent through the manufacturing process multiple times, such as polystyrene (or styrofoam), PE can be useful through many life spans, reducing demand for our natural resources.

2. Avoids Landfills

As the human population increases year over year, the need for landfills also increases. The Environmental Protection Agency estimates that about 27 million tons of plastic ended up in landfills in 2017. This is a 10 percent increase from a decade earlier, which may indicate a rapidly escalating situation.

When PE products are recycled, they can have a positive environmental impact. Instead of turning into plastic waste that fills up landfills, these products can be used to create other products through recycling programs. Diverting PE to recycling plants helps reduce the public demand on landfills, which often lack the resources to recycle these materials themselves.

3. Reduce Pollution

With widespread concerns about a changing climate, manufacturers, brands, and consumers are all looking for ways to curb pollution.

During the production of virgin plastics, CO2 and other greenhouse gasses are released. These gasses have the potential to cause public health issues and environmental damage.

Transforming existing plastics into new recycled products can help offset and reduce greenhouse gas emissions and reduce pollution in our oceans, landfills, and communities.

4. Ease Reliance on Fossil Fuels

Recycling PE products can help to reduce our carbon footprint in general. Manufacturing virgin plastics is a resource-intensive process: millions of barrels of crude oil are needed to meet yearly demand.

Collecting and recycling perfectly useful PE products may limit our reliance on fossil fuels. The process of creating new products from already used plastics is much less intensive than manufacturing from scratch.

Dymapak’s Recycling Efforts

Dymapak understands the importance of sustainability and has made efforts to reduce our carbon footprint while delivering quality packaging materials to our clients.

Our flexible bags require fewer virgin materials and, as such, lessen the impact on the environment compared to typical rigid packaging.

Secure Sack Eco

In line with our commitment to recycling and sustainability efforts, we have created the Secure Sack Eco.

The Secure Sack Eco is the world’s first recyclable, lab-certified, and child-resistant bag. It delivers the security, safety, and reliability of all Dymapak products while reducing the impact of plastic packaging on the environment.

The lightweight and flexible Secure Sack Eco is constructed of recyclable PE films, helping your brand to achieve recyclability goals without sacrificing barrier protection.

The Bottom Line

Polyethylene is undoubtedly an important technological development that has benefited many industries. When making decisions about packaging and manufacturing, it should be at the top of your list as a brand. Dymapak is here to help make it happen.

It is valuable for its ability to protect the integrity of products and its recyclability. By switching to PE packaging, brands can contribute to sustainable and environmentally conscious living and business practices.

Sources:

7 Things You Didn’t Know About Plastic (and Recycling) | National Geographic

Facts and Figures on Materials, Wastes, and Recycling | EPA

LDPE vs HDPE | University of Texas

Consumers Demand Sustainable Products And Shopping Formats | Forbes